Laser-based Sample Preparation for FA: microPREP® PRO and microPREP® PRO FEMTO

Exhibitor

3D-Micromac AG

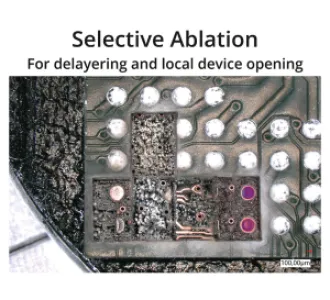

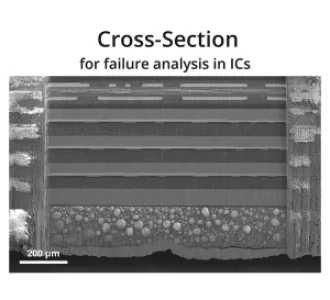

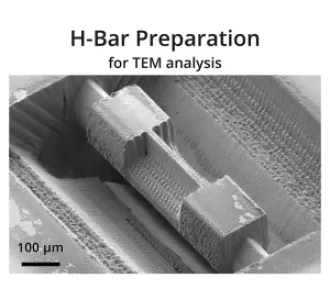

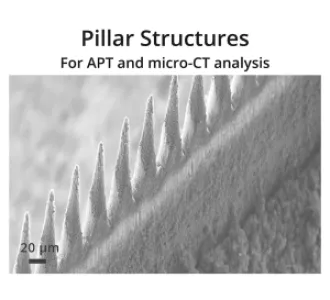

microPREP® PRO FEMTO is 3D-Micromac’s high-precision laser ablation system engineered explicitly for advanced sample preparation tasks in semiconductor failure analysis and device characterization. Equipped with a femtosecond laser, it enables high-resolution cross-sectioning and delayering with minimal thermal and mechanical impact, making it ideal for preparing complex, multilayer semiconductor structures.

Unlike conventional methods such as mechanical polishing or ion beam milling, microPREP PRO FEMTO uses ultrashort laser pulses to selectively remove material while preserving structural integrity and analytical fidelity. Compared to FIB systems, the laser-based process is significantly faster, especially when preparing larger areas or coarse material removal is required. That makes it a powerful, non-destructive, and time-saving alternative—or complementary front-end tool—to traditional FIB and other established preparation techniques.

The system is also capable of processing larger samples and packages automatically, supporting a broad range of specimen geometries and materials, including metals, semiconductors, ceramics, polymers, and advanced composites. A user-friendly software environment with predefined workflows ensures reproducibility and seamless integration into existing analysis workflows, including SEM, TEM, APT, X-ray tomography, and micromechanical testing.

By reducing time-to-sample and minimizing tool bottlenecks, microPREP PRO FEMTO increases throughput, lowers the cost of ownership, and enhances lab efficiency, particularly in semiconductor labs that deal with growing sample volumes and increasing complexity.

Laser-based sample preparation speeds up Failure Analysis (FA) and quality inspection tasks